Capacity Management Glossary: Key Terms

Definition of Production capacity

What is production capacity?

Production capacity is the maximum amount of products or services an organization can produce in a given period under normal working conditions, using its available resources effectively. It reflects how much output your operation can handle before performance, quality, or efficiency starts to decline.

In both manufacturing and service industries, production capacity is determined by multiple factors: workforce skills, equipment capability, process efficiency, material/tool availability, and technology infrastructure. It's not just about "pushing output higher"—true capacity is about achieving optimal performance without overloading the system.

What is production capacity in business?

In a business context, production capacity represents an organization's ability to meet customer demand without creating bottlenecks or compromising quality. Capacity is a key element in strategic planning, investment decisions, and financial forecasting—because it determines how much value you can deliver to the market and at what cost.

If capacity is too low, you risk losing revenue opportunities. If it's overestimated, you could end up with wasted resources and inflated operating costs. Successful companies monitor and adjust capacity continuously to stay aligned with demand.

Why is production capacity important?

Productivity and profitability often hinge on how well you understand and manage capacity. Here's why it matters:

- Operational efficiency

Understanding your true capacity prevents both overproduction and underproduction. When you produce more than demand requires, you tie up cash in excess inventory. When you produce too little, you face missed deadlines and rushed orders. Effective capacity management deploys resources where they create maximum value, eliminating waste and maintaining smooth operations. - Customer satisfaction

Accurate capacity planning ensures you deliver orders completely and on time. When you know exactly what you can produce, you avoid overcommitting and disappointing customers. This reliability builds long-term relationships and strengthens your market reputation. - Strategic agility

Clear capacity insights help you respond quickly to market changes. Whether facing seasonal surges, new product launches, or unexpected demand shifts, understanding your production limits enables better forecasting and resource allocation. This agility keeps you competitive when others struggle with rigid planning. - Bottleneck prevention

Capacity analysis reveals potential constraints before they disrupt workflow. By identifying where shortages might occur—whether in staffing, equipment, or materials—you can invest in solutions early. This proactive approach prevents small issues from becoming major disruptions. - Cost control

Optimized capacity planning aligns your spending with actual output needs. You invest in labor, materials, and equipment based on realistic production goals, avoiding costly overtime or idle resources. This precision supports accurate budgeting and drives sustainable profitability.

In short, understanding production capacity ensures you're producing at a level that supports business growth without sacrificing operational stability.

How to calculate production capacity?

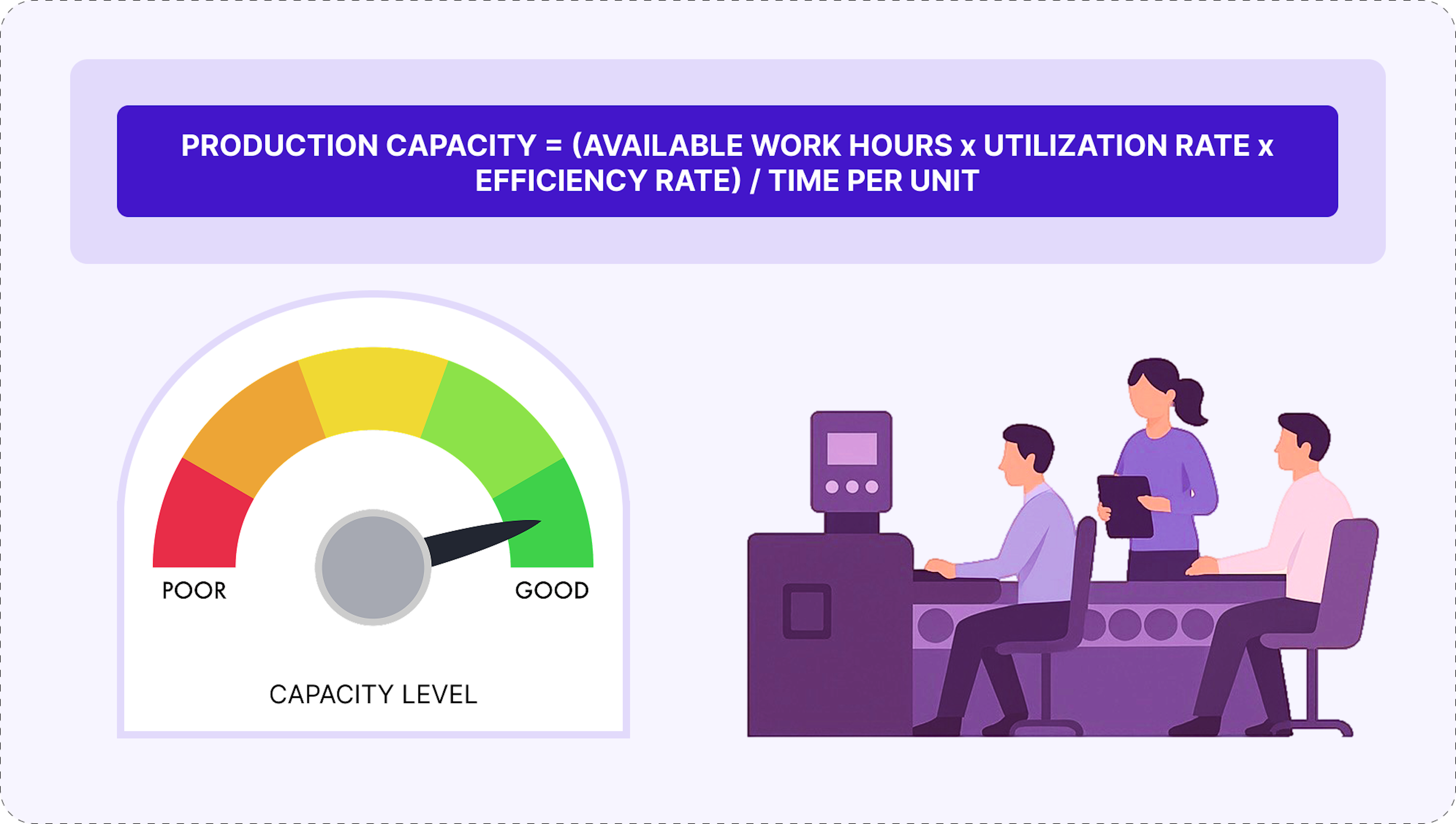

The calculation depends on the industry and type of output, but the basic formula for manufacturing or service operations is:

Production capacity = (Available work hours × Utilization rate × Efficiency rate) / Time per unit

- Available work hours – Total hours your workforce and equipment are available.

- Utilization rate – The percentage of available time actually used for production.

- Efficiency rate – How effectively resources are used without waste.

- Time per unit – Average time needed to produce one unit.

EXAMPLE OF CALCULATION IN TECH INDUSTRY

If a team works 1,000 hours per month, operating at 85% utilization (the percentage of available time spent on productive work) and 90% efficiency (how effectively that productive time converts into output), and produces each unit in 0.5 hours, then:

Capacity = (1000 × 0.85 × 0.90) / 0.5 = 1530 units/month

In this case, the unit of production could represent any discrete deliverable relevant to the team's work—such as a software feature, a manufactured component, or a customer ticket resolved.

Regularly tracking this capacity calculation enables managers to spot shifts in utilization or efficiency early, revealing trends in available capacity. These insights signal when process improvements, workload balancing, or resource adjustments (e.g., hiring or training) are necessary to sustain or increase output without burning out the team.

How can Enji help increase production capacity?

Enji enables companies, especially in software development and service delivery, to improve capacity without necessarily adding headcount or capital expenses by making operations more transparent and efficient.

Here's how Enji supports capacity growth:

- Agile metrics dashboard – Visualizes cycle time, lead time, and estimation accuracy so you can pinpoint process inefficiencies slowing delivery.

- Enlightening worklogs – Compares planned vs. actual hours per employee, showing where work is unevenly distributed or underutilized.

- Bottleneck detection – Pull Request Analytics and SOW Planning highlight blocked tasks, excessive review times, and overloaded teams—so work can be reassigned before deadlines slip.

- Automated alerts – Notifies managers when key performance indicators (e.g., lead time, PR queue size) suggest capacity constraints.

- Data-driven resource allocation – Links time usage and performance metrics to project budgets, letting you decide where to invest extra resources for the most capacity impact.

Example: Suppose your code review stage consistently slows product releases. Enji pinpoints the exact time consumed in this phase, quantifies its impact on overall cycle time, and identifies teams or individuals who can share the workload. This insight helps increase throughput speed without sacrificing quality.

Key Takeaways

- Production capacity is the maximum sustainable output your organization can deliver in a given time.

- In business, it determines your ability to meet demand cost-effectively and without quality trade-offs.

- Capacity management is essential for efficiency, customer satisfaction, and profitability.

- You can calculate production capacity with a simple formula that factors in available hours, utilization, efficiency, and time per unit.

- Enji helps increase capacity by enabling data-driven bottleneck resolution, better workload distribution, and proactive operational adjustments.

Last updated in August 2025